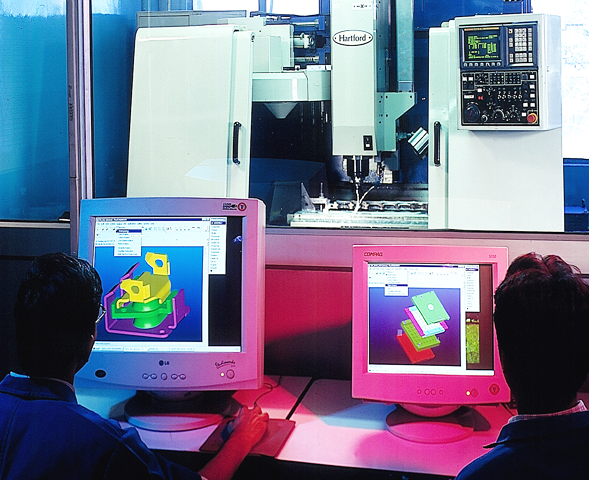

UG-Ideas

Pro-E

CAD/CAM softwares

Vertical Machining Centre

Electric Discharge Machine

CNC Wire Cutting Machines

Centreless & Cylindrical Surface Grinders

Milling Machine

Hydraulic Surface Grinders

Die Sinking Machine

Shaping/Planning Machines

Semi-Automatic & Turret Lathes

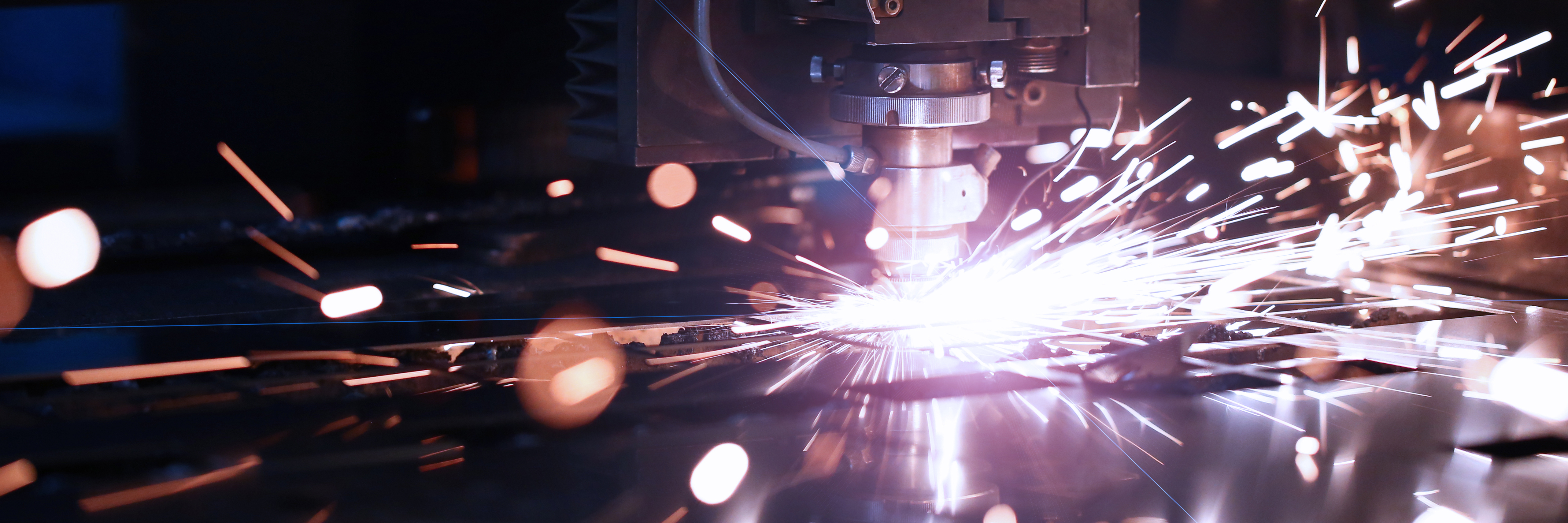

MIG, ARC & Spot Welding Machines

Broaching Machines & Boring Machines

State-of-the-art sheet metal presses ranging from 25 to 300 tons Presses

Japanese, Korean & Taiwanese

Mechanical Hydraulic Presses installed with Auto De-coilers, Auto feed mechanisms for high productivity

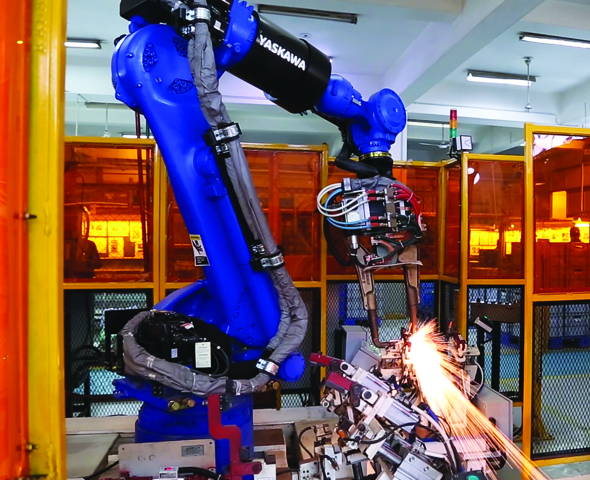

Robotic MIG Welding

Robotic Spot Welding

Inhouse weld penetration checking equipments & UTM for welding strength